Carbon - Cruising Mainsail

An Italia 12.98 with X-Drive carbon full-batten mainsail and roller/furling genoa. The base laminate has a white taffeta on the side opposite the fibers, while the main has taffeta applied over the fibers on the leech for extra durability.

An example of the nearly full coverage of carbon fibers on a mainsail.

Carbon fiber is the highest performance yarn used in sailmaking. As seen below, carbon yarns are at the top of the chart in three out of four ways to measure their performance. Carbon fiber’s resistance to stretch is three times greater that S-Glass yarns, which are, in tern, three times more stretch resistant than polyester yarns.

Even though the individual fibers in an X-Drive sail are very narrow, their almost complete coverage of the sail leads to a smooth flying shape. UK Sailmakers’ fiber laying machine puts down up to 11 tapes at a time, which means there are hundreds of continuous fibers running across the sail. Since each carbon fiber has 4000 carbon filaments there are up to 44,000 filaments of carbon are laid at time, giving the sail great strength along with the ability to keep its designed shape. This means UK Sailmakers can use lighter and less expensive laminates than other sailmakers and that savings is passed on.

All the carbon yarns used in X-Drive tapes are dry (not coated in glue) which keeps them from becoming brittle. Keeping the carbon yarns dry improves their flexibility.

A Linjett 43 with X-Drive carbon sails for both cruising and club racing. On this sail, a taffeta layer has been bonded over all the X-Drive fibers for more durability.

Close-up of carbon X-Drive fibers on a polyester laminate.

Batten Configuration Options

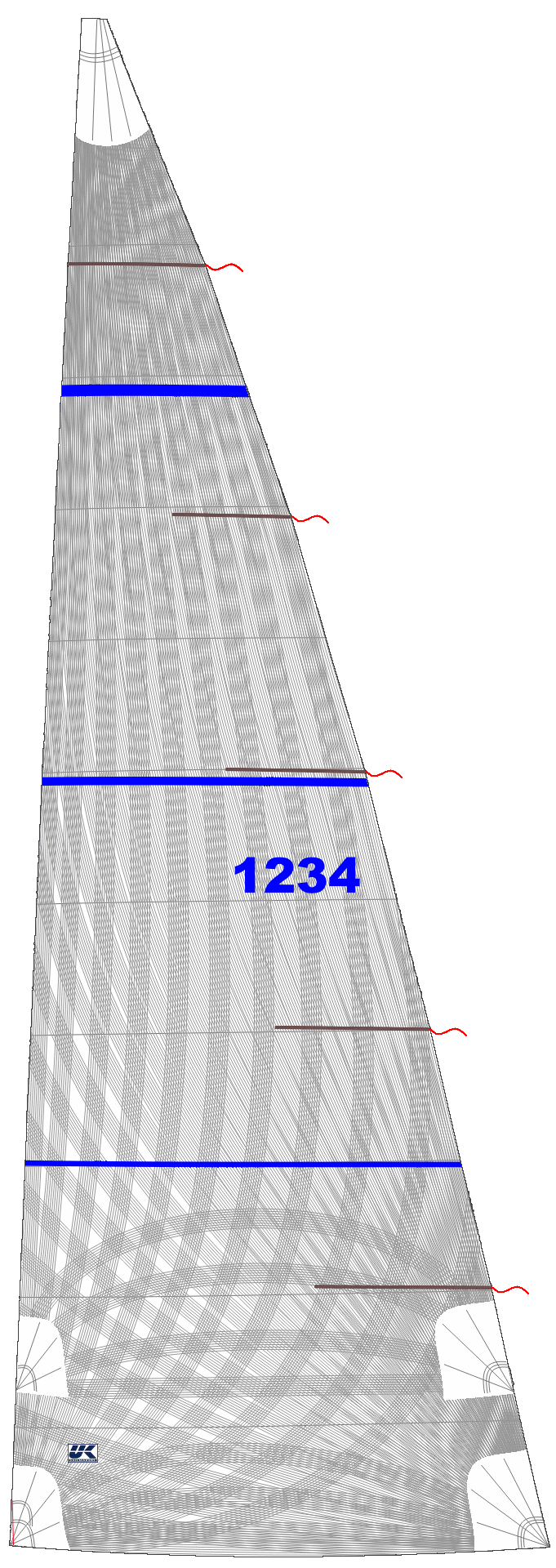

POWERHEAD 1

For maximum roach mainsails, UK Sailmakers builds sail with a full-length top batten. The batten running leech to luff stabilizes the leech while projecting the narrowest part of the sail fully.

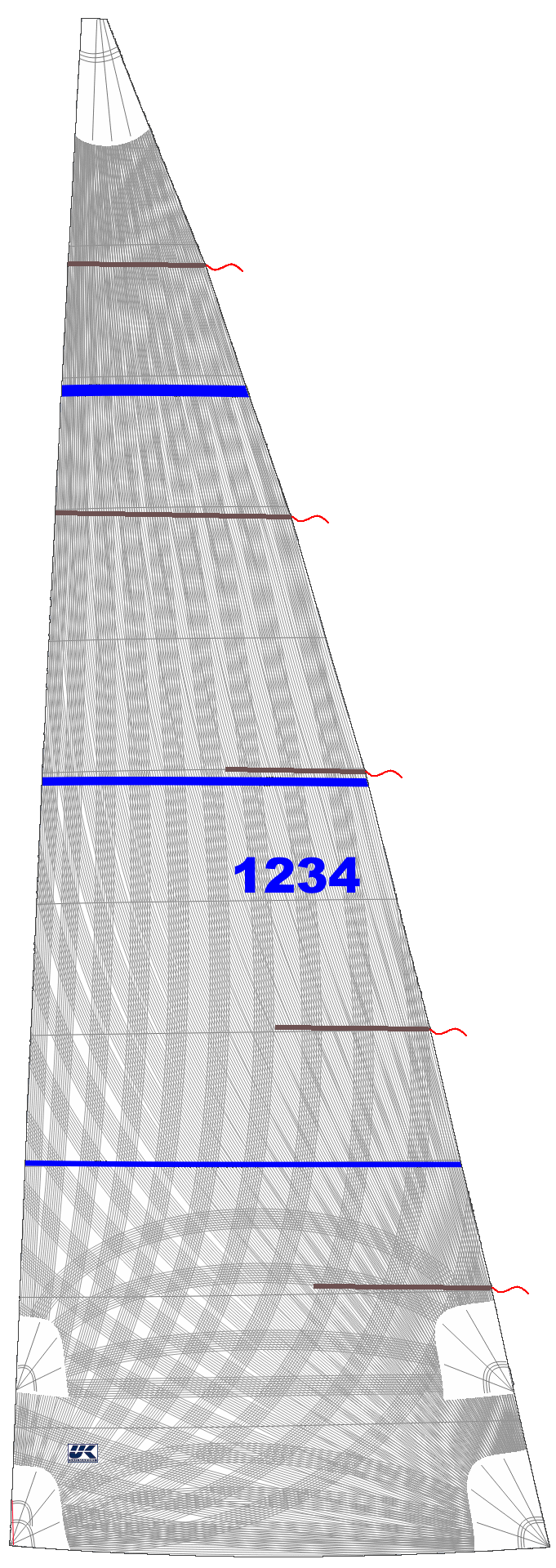

POWERHEAD 2

For sails with extra roach or that have a lower aspect ratio, we offer two full-length top battens. The combination of full-length upper battens and shorter leech battens in the best of the sail combines the positive properties of both batten systems. The full-length battens support the large roach and add longevity to the highly loaded head section of the sail. The shorter battens sail reduces weight and allows for better sail shape control.

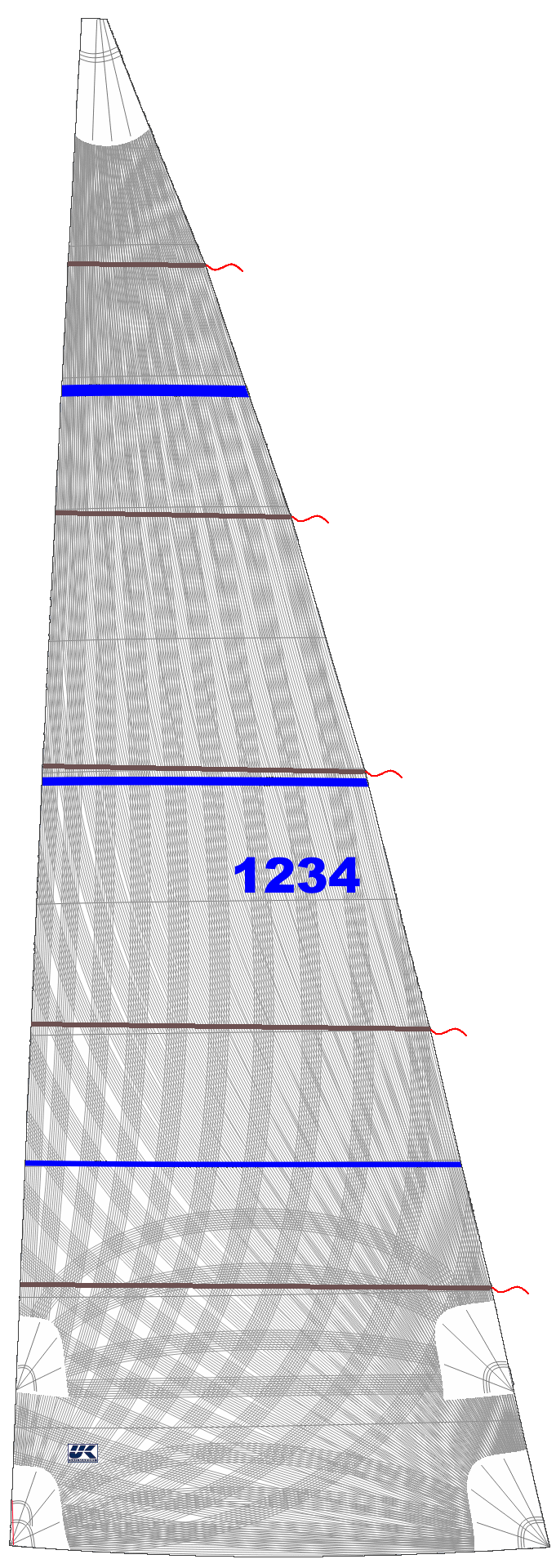

BATMAIN

The full-length battens that run from leech to luff make the Batmain the longest lasting mainsail you can buy. The battens prevent your sail from flogging, which is the prime culprit of wear-and tear. The full length battens work well with sailhandling systems like lazy jacks, The Dutchman system and the UK Lazy Cradle since the battens help keep the folds of sail inside the lazy jack lines.

IN-MAST FURLING MAINS

The most common furling main is the in-mast main with no battens. Without battens the sail can be rolled and unrolled on any point of sail. Many production cruising boats come standard this way. Furling mains can be made with vertical battens that support some roach, which greatly improves the boat’s performance. Sails with vertical battens will need to be rolled and unrolled when the boat is pointed into the wind. Vertical battens can be partial length or full length. Mainsails can also be made to roller furl into booms; these sails have full length horizontal battens.

Extra Durability With Taffeta

To help protect today’s sails and extend their peak performance lives, UK Sailmakers can build all our X-Drive racing sails where one or both sides of the laminate is fully covered with a lightweight finely-woven polyester taffeta. Not only does taffeta protect the film layer from abrasion, but it also prevents cracking of the film and reduces creasing. While taffeta doesn't add much strength, it does make sails last longer. We also offer the option of putting a layer of taffeta over the X-Drive fibers only on the leech of the sail as shown below.

Taffeta is available in white or a medium grey color.

Partial Taffeta Option

Shown above is a Dehler 34 main with taffeta on one full side and over the fibers on the second side.

The leech of any sail benefits from having extra taffeta protection. Adding taffeta to the leech of an X-Drive mainsail reduces the destructive effects of leech flutter, luffing and flogging. Mainsails can flog in heavy air as the boat is de-powered and when the sail is being hoisted or lowered. Leech flutter happens when the leech line is not properly tensioned. The X-Drive construction method allows sailors to choose a sail with taffeta on one side of the sail, on one side and on the leech of the second side, or fully covering both sides. The more taffeta, the more protection -- at the cost of more weight aloft.

UK Sailmakers will work with you to determine the right amount of taffeta to add to your sails based on your boat, the kinds of sailing you do, and your budget. Having both sides covered with taffeta makes a sail more durable, but also would make the sail heavier. UK Sailmakers offers a Partial Taffeta option to save weight and cost.

Available Details

Available with:

- Reef

- Loose Foot

- Cunningham

- Telltales

- Draft Stripes

- Sail Numbers

- Leechline

Options

Available with:

- Partial Taffeta

- Double Taffeta

Battens:

- Powerhead

- Full Battens

- Furling Mains

Other Options:

- Lazy Cradle

- Lazy Jacks

- Dutchman

- Sail Cover